The Evolution of Chinese Sword-Making Techniques

TLDR: The article explores the evolution of Chinese sword-making techniques from the Bronze Age to the Qing Dynasty, highlighting advancements in materials, designs, and craftsmanship that shaped iconic swords like the Jian and Dao.

You know, there’s something truly magical about Chinese swords. I mean, just imagine holding a piece of history that’s been forged by master craftsmen over thousands of years! The evolution of Chinese sword-making techniques is like this epic journey through time, filled with incredible innovations and jaw-dropping craftsmanship. From the early days of bronze casting to the mind-blowing steel folding techniques of the Ming and Qing dynasties, it’s a story that never fails to amaze me.

Early Bronze Age Sword-Making (c. 2000 BC – 500 BC)

The dawn of Chinese sword-making can be traced back to the Early Bronze Age, a period spanning from around 2000 BC to 500 BC. This era marked a significant milestone in Chinese metallurgy, as bronze swords were introduced and rapidly became symbols of power and technological prowess.

The introduction of bronze swords in China revolutionized warfare and craftsmanship. Early Chinese metalsmiths developed sophisticated casting techniques to produce these weapons. They primarily used piece-mold casting, a method unique to ancient China. This technique involved creating intricate clay molds in sections, which allowed for more complex designs and better control over the final product compared to the lost-wax method used elsewhere in the ancient world.

The composition of bronze alloys used in sword-making during this period was crucial to the weapons’ effectiveness. Chinese bronzesmiths experimented with various ratios of copper and tin, sometimes including lead, to achieve the desired balance of hardness and durability. A typical bronze sword from this era might contain:

| Element | Percentage |

| Copper | 80-85% |

| Tin | 10-15% |

| Lead | 0-5% |

Notable bronze swords from the Western Zhou period (1046-771 BC) showcase the advanced skills of early Chinese sword-makers. These swords often featured:

- Intricate decorations on hilts and pommels

- Tapered blades for improved balance and thrust

- Inscriptions detailing ownership or purpose

Advancements in Bronze Sword Forging (500 BC – 200 BC)

The period between 500 BC and 200 BC witnessed significant advancements in bronze sword forging techniques in ancient China. This era saw the development of composite bronze sword techniques that revolutionized weapon craftsmanship and military technology.

One of the most notable innovations during this time was the two-times casting method for bi-metallic swords. This technique involved a sophisticated process where swordsmiths would first cast the core of the sword using bronze with a lower tin content, typically around 10-15%. This softer core provided flexibility and prevented the sword from shattering upon impact. Subsequently, they would cast a high-tin bronze alloy, containing approximately 15-21% tin, around the edges of the sword. This two-step casting process resulted in a blade with a hard, sharp edge and a more flexible core, combining the best properties of both alloy compositions.

The evolution of Chinese sword-making techniques during this period also saw the refinement of creating high-tin bronze edges over softer, lower-tin cores. This method allowed for the production of swords with exceptional cutting ability while maintaining overall durability. The high-tin content in the edge increased the hardness of the blade, making it capable of holding a sharper edge for longer periods. Meanwhile, the lower-tin core ensured the sword remained tough and resistant to breaking during combat.

A prime example of the advanced bronze sword-making techniques from this era is the famous Sword of Goujian, dated to around 500 BC. This remarkable weapon showcases several unique properties:

- Exceptional preservation, remaining sharp and untarnished after over 2,000 years

- Intricate inscriptions and decorations on the blade

- A black rhombic pattern on the blade, believed to be an early form of anti-rust technology

- Superior craftsmanship in its overall design and balance

Transition from Bronze to Iron Swords (200 BC – 200 AD)

The transition from bronze to iron swords in China, occurring between 200 BC and 200 AD, marked a significant evolution in Chinese sword-making techniques. This period saw the gradual introduction of iron swords in Chinese warfare, revolutionizing military technology and tactics.

Iron swords began to appear in China around the 3rd century BC, during the late Warring States period. However, the adoption of iron weaponry was not immediate or universal. For several centuries, bronze and iron swords coexisted on Chinese battlefields. This coexistence was due to several factors, including the established tradition of bronze craftsmanship, the initial challenges in iron production, and the varying availability of raw materials across different regions.

As iron smelting and forging techniques improved, the quality of iron swords increased significantly. Chinese metalsmiths developed methods to create stronger and more durable iron blades. These improvements included:

- Better furnace designs for higher temperatures

- Refined smelting processes to reduce impurities

- Advanced forging techniques to improve blade strength

- Innovative quenching methods for increased hardness

The Han Dynasty (202 BC – 220 AD) witnessed a crucial development in sword-making: the emergence of steel swords. Steel, an alloy of iron and carbon, offered superior properties compared to pure iron. Han Dynasty metalsmiths discovered that by controlling the carbon content and using specific heat treatment processes, they could produce blades that were both hard and flexible.

Steel Sword-Making Innovations (200 AD – 600 AD)

The period from 200 AD to 600 AD marked a significant era of innovation in Chinese sword-making techniques, particularly in the realm of steel production and refinement. During this time, Chinese metalsmiths made remarkable strides in improving the quality and performance of their steel swords.

One of the most notable advancements was the refinement of steel production methods. Swordsmiths developed more sophisticated techniques for controlling the carbon content in iron, which is crucial for creating high-quality steel. They experimented with various alloys and forging techniques, including a method called “pattern welding,” which involved layering and forging different metals to create composite materials with superior strength and intricate patterns.

Compound steel techniques and edge tempering became increasingly sophisticated during this period. Swordsmiths began using forge-welding or lamination methods, employing higher carbon steel for the cutting edge and lower carbon steels for the core or spine of the sword. This technique resulted in blades with exceptional cutting ability and overall durability. Edge tempering, a process of carefully heating and cooling the blade’s edge, further enhanced the sword’s hardness and sharpness.

The evolution of Chinese sword-making techniques during this era also saw the perfection of repeated forging to remove impurities and distribute carbon more evenly within the steel. This process, known as “folding,” involved heating, hammering, and folding the steel multiple times. Archaeological findings have revealed swords from this period with up to 30 or even 50 folds, demonstrating the meticulousness of the craftsmen.

Perhaps the most significant innovation of this period was the introduction of the “refined steel” technique, known as “bai lian gang” or “hundredfold refining.” This method involved repeated heating, folding, and hammering steps to produce a layered steel of exceptional quality. The process could involve anywhere from 30 to 100 folds, with each iteration improving the steel’s uniformity and reducing impurities.

The advancements in steel sword-making during this period can be summarized in the following table:

| Innovation | Description | Impact |

| Refined steel production | Better control of carbon content | Improved overall steel quality |

| Compound steel techniques | Layering different steel types | Enhanced blade performance |

| Edge tempering | Selective heat treatment of edges | Increased hardness and sharpness |

| Repeated forging | Multiple folding and hammering | Reduced impurities, even carbon distribution |

| “Bai lian gang” technique | Hundredfold refining process | Produced exceptionally high-quality steel |

I’m utterly fascinated by the level of craftsmanship and metallurgical knowledge these ancient swordsmiths possessed. The patience and skill required to fold steel dozens of times, carefully controlling temperature and composition, is truly awe-inspiring.

Tang Dynasty Sword-Making Revolution (618 AD – 907 AD)

The Tang Dynasty (618 AD – 907 AD) marked a revolutionary period in the evolution of Chinese sword-making techniques. This era saw significant advancements in both the craftsmanship and design of swords, cementing China’s reputation for producing some of the finest blades in the world.

One of the most notable innovations during this period was the development of the “wrapped steel” technique. This method involved wrapping a softer iron core with harder, high-carbon steel. The result was a blade that combined the flexibility of the core with the hardness and sharpness of the outer layer, creating a sword that was both durable and lethal. This technique, also known as “kobuse” technology, allowed swordsmiths to optimize the use of different steel types, embodying the principle of “good steel is used on the blade”.

Advancements in blade geometry and balance were also hallmarks of Tang Dynasty sword-making. Swordsmiths widened the blade and extended the handle, allowing for a two-handed grip that increased power and control. These changes in proportions significantly improved the sword’s overall balance and handling characteristics, making it more effective in combat situations.

The Tang Dynasty also saw the introduction of new pommel designs and handle materials. Swordsmiths began incorporating round or square handguards, a feature previously unseen in Chinese swords. These additions not only enhanced the sword’s aesthetic appeal but also provided better protection for the wielder’s hand. The use of various materials for handles, such as wood wrapped with silk rope, further improved grip and comfort.

The influence of Tang swords extended far beyond China’s borders. Many Tang swords were exported to neighboring regions, particularly Japan. This cultural exchange had a profound impact on Japanese sword-making, with several Tang swords now considered national treasures in Japan. The superiority of Tang swords even influenced the development of thicker-bladed swords in Japan during later periods.

Key features of Tang Dynasty swords:

- Composite steel construction (wrapped steel technique)

- Wider blades and longer handles for two-handed use

- Introduction of handguards

- Improved balance and handling

- Significant influence on foreign sword-making traditions

Song and Yuan Dynasty Sword Craftsmanship (960 AD – 1368 AD)

The Song and Yuan Dynasties (960 AD – 1368 AD) marked a period of significant advancement in Chinese sword-making techniques. During this era, swordsmiths achieved further refinements in steel quality and composition, pushing the boundaries of metallurgy to create blades of exceptional strength and durability.

In the Song Dynasty, under Emperor Shenzong’s reign, the technical quality of Chinese weapons reached new heights. Swordsmiths perfected the process of folding and forging steel, resulting in blades with improved strength and flexibility. They also experimented with different alloy compositions to enhance the sword’s performance in various combat situations.

The evolution of Chinese sword-making techniques during this period led to the development of specialized sword types for different combat roles. One notable example is the Zhanmadao, or “horse-cutting sword,” which was specifically designed to counter armored cavalry. This massive two-handed sword, with a blade length of about 3 feet and a 1-foot handle, was capable of cutting through enemy armor and horses, demonstrating the Song Dynasty’s innovative approach to weapon design.

Decorative elements became increasingly integrated into sword design during this era. Swordsmiths began incorporating intricate patterns and engravings on blades, hilts, and scabbards. These decorations not only enhanced the aesthetic appeal of the swords but often carried symbolic meanings or represented the owner’s status.

The Mongol invasion and subsequent establishment of the Yuan Dynasty brought significant changes to Chinese sword-making techniques. The influence of Mongolian curved sabers became prominent, leading to the development of heavier, thicker, and more curved blades. This shift in design was particularly suited for mounted combat, reflecting the Mongols’ cavalry-centric warfare.

Key developments in Song and Yuan Dynasty sword craftsmanship:

- Improved steel folding and forging techniques

- Introduction of the Zhanmadao for anti-cavalry warfare

- Integration of decorative elements with practical designs

- Adoption of Mongolian-influenced curved blade designs

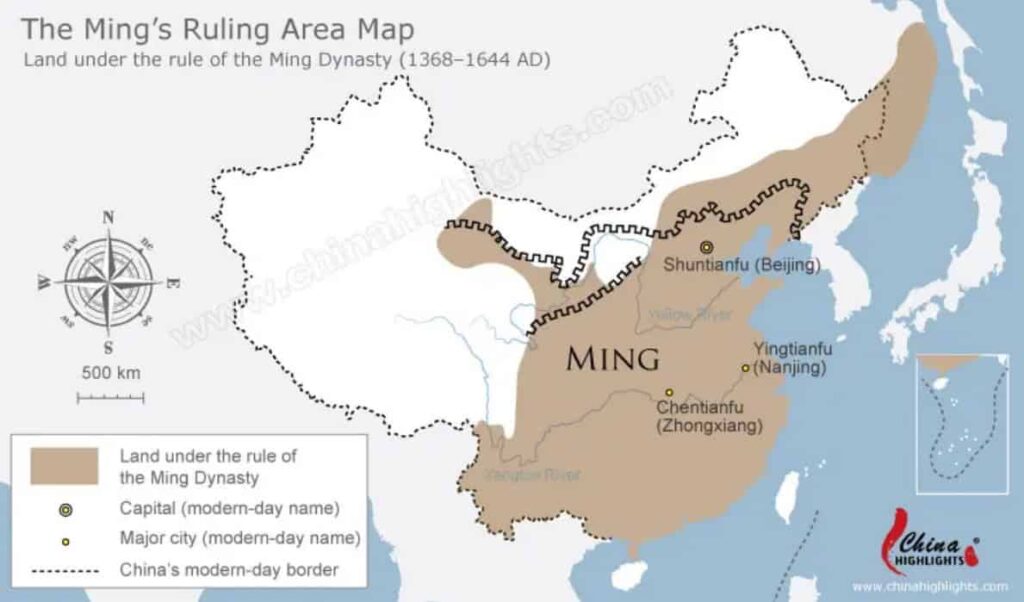

Ming and Qing Dynasty Sword-Making Mastery (1368 AD – 1912 AD)

The Ming and Qing Dynasties (1368 AD – 1912 AD) marked the pinnacle of Chinese sword-making techniques, with craftsmen achieving unprecedented levels of skill and artistry. During this period, swordsmiths perfected the folded steel techniques that had been developing for centuries. They refined the process of repeatedly heating, folding, and hammering steel to create blades with exceptional strength and flexibility. This method not only removed impurities but also ensured an even distribution of carbon throughout the blade, resulting in swords of superior quality.

Advanced heat treatment methods were introduced during this era, further enhancing the performance of Chinese swords. Swordsmiths developed sophisticated quenching techniques, often using a combination of water and oil to achieve the ideal cooling rate. This double liquid quenching method allowed for the creation of blades with high hardness and good toughness while minimizing the risk of deformation or cracking. The mastery of heat treatment became a hallmark of skilled swordsmiths during this period.

The evolution of Chinese sword-making techniques during the Ming and Qing Dynasties also saw the development of specialized tools for sword crafting. These tools allowed for more precise shaping and finishing of blades, hilts, and scabbards. Swordsmiths used various implements such as spatulas, cutters, and files to trim and refine sword blanks, ensuring that each weapon met exacting standards of form and function.

One of the most notable aspects of Ming and Qing Dynasty sword-making was the creation of ornate and ceremonial swords for the imperial court. These weapons were not only functional but also served as symbols of power and status. Craftsmen adorned these swords with precious metals and gemstones, creating intricate designs that showcased the highest levels of artistry. The Yan Ling Dao, a recognizable Chinese saber of the Ming Dynasty, exemplifies this blend of functionality and aesthetics with its slightly curved blade and elaborate decorations.

Key developments in Ming and Qing Dynasty sword-making:

- Refinement of folded steel techniques for superior blade quality

- Implementation of advanced double liquid quenching methods

- Use of specialized tools for precise craftsmanship

- Creation of highly decorative ceremonial swords

Notable Sword-Making Regions and Schools

The evolution of Chinese sword-making techniques is deeply rooted in regional traditions and schools, each contributing unique elements to the craft. Among the most notable were the Wu and Yue states, which played a crucial role in early sword technology. During the Spring and Autumn period (770-476 BC), while central China primarily used halberds and spears, the Wu and Yue states excelled in sword craftsmanship. Their swords, such as the famous blades of King Fuchai of Wu and King Goujian of Yue, were renowned for their exceptional length, often exceeding 50 cm, and superior quality.

The Longquan sword-making tradition, originating in Longquan County of Zhejiang Province, stands out as a pinnacle of Chinese sword craftsmanship. This region became the production center for swords following the innovations of Ou Yezi (560-510 BC), who is credited with creating the Longquan sword. The unique iron sand found in Longquan contributed to the exceptional resilience and strength of blades produced there. Today, Longquan continues to be a hub for sword-making, with numerous workshops and some of China’s top swordsmiths calling it home.

Famous sword-making families often passed down their techniques through generations, refining and perfecting their craft. These families developed distinctive styles and methods, contributing to the rich diversity of Chinese swords. For instance, the Zhang family, represented by artisans like Zhang Yesheng, became known for creating swords that epitomize the highest quality of Longquan craftsmanship.

Regional variations in sword design and craftsmanship were significant, reflecting the diverse needs and cultural influences across China. Northern swords, for example, were often heavier and longer, suited for open-field combat, while southern versions tended to be shorter, optimized for close combat in forested and hilly terrains. These regional distinctions not only showcased the adaptability of Chinese sword-makers but also highlighted the intricate relationship between geography, warfare tactics, and weapon design.

| Region | Notable Contribution |

| Wu and Yue | Early long-bladed swords |

| Longquan | High-quality, resilient blades |

| Northern China | Heavy, long swords for cavalry |

| Southern China | Compact swords for forest combat |

Technological Breakthroughs in Chinese Sword-Making

The evolution of Chinese sword-making techniques saw significant technological breakthroughs over the centuries, particularly in the areas of furnace design, metallurgy, and heat treatment processes. These advancements allowed Chinese swordsmiths to produce blades of exceptional quality and performance.

One of the most crucial developments was the evolution of furnace designs for better temperature control. Early Chinese furnaces were simple pit structures, but over time, they evolved into more sophisticated designs with better insulation and airflow control. By the Tang Dynasty, swordsmiths were using furnaces that could achieve and maintain the high temperatures necessary for working with high-carbon steels. These improved furnaces allowed for more precise control over the heating and cooling processes, which was essential for creating blades with consistent quality.

The development of flux materials marked another significant breakthrough in Chinese sword-making. Fluxes are substances used to promote the fusing of metals and remove impurities during the smelting process. Chinese swordsmiths experimented with various flux materials, including plant ashes and mineral compounds, to improve the quality of their steel. These innovations resulted in cleaner, stronger steel that was better suited for sword production.

Innovations in quenching and tempering processes were particularly important in the evolution of Chinese sword-making techniques. Chinese swordsmiths developed sophisticated methods for differential heat treatment, similar to the Japanese technique of clay tempering. This process involved coating parts of the blade with clay before quenching, allowing for different cooling rates across the sword. The result was a blade with a hard, sharp edge and a more flexible spine, combining the best properties of both hard and soft steels.

Advancements in surface treatment techniques, such as “dip or wipe tinning,” further enhanced the quality and appearance of Chinese swords. This process involved applying a thin layer of tin to the surface of the blade, which not only improved its resistance to corrosion but also gave it a distinctive appearance. The technique was particularly prevalent during the Tang Dynasty and contributed to the renowned beauty of swords from that era.

Key technological breakthroughs in Chinese sword-making:

- Improved furnace designs for precise temperature control

- Development of effective flux materials for purer steel

- Differential heat treatment techniques for optimal blade properties

- Advanced surface treatments for enhanced durability and aesthetics

| Era | Technological Breakthrough |

| Early dynasties | Basic pit furnaces |

| Tang Dynasty | Advanced furnaces with better temperature control |

| Song Dynasty | Refined flux materials for higher quality steel |

| Ming Dynasty | Sophisticated differential heat treatment techniques |

Final Thoughts

Looking back on this incredible journey through Chinese sword-making history, I can’t help but feel a sense of awe. It’s mind-boggling to think about how these ancient craftsmen pushed the boundaries of metallurgy and design, creating weapons that were not just tools of war, but true works of art. In my opinion, the evolution of Chinese sword-making techniques is a testament to human ingenuity and the relentless pursuit of perfection. From the humble beginnings of bronze casting to the legendary blades of the Qing Dynasty, each era brought its own unique contributions to this ancient art.